French oak or American Oak, French cement or American cement?

French oak or American Oak, French cement or American cement? … to be or not to be, that was once the question?

Now, according to the owner of Bodega Luna Austral, Lucia Busnelli, the anti has just gone up in Mendoza, and winemakers are now flocking towards Biodynamism, all certificated by Demeter of course, and also now using ‘cement eggs’ made in France.

I understand the tremendous usefulness of B-D, also the certificate comes in handy, but when I asked, why do they import?, at such great expense, these ‘cement eggs’ from France. I was told, clearly, that French cement is the best. I could not beleive what I was hearing. So I had to double check that this is indeed what she had said. Yes, French cement is the best, infact we could almost go one further and say that it the best cement in the world. Now, not having spent a lot of my time on any building sites, I am not really up on what is good cement and what is not good cement. So I have to make a little study that I now want share with you, before we go onto what 2013 and 2012 Luna Austral Malbec tastes like alongside 2013 Sintonia, both made on the same estate in Valle de Uco, Mendoza by the legendary B-D winemaker, Alvaro Espinoza, wow!

So what is Cement? oh no, are we really going to do this?

Cement is the basic ingredient of concrete. Concrete is formed when cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high temperatures form a rock-like substance that is ground into the fine powder that we commonly think of as cement.

Bricklayer Joseph Aspdin of Leeds, England first made portland cement early in the 19th century by burning powdered limestone and clay in his kitchen stove. With this crude method, he laid the foundation for an industry that annually processes literally mountains of limestone, clay, cement rock, and other materials into a powder so fine it will pass through a sieve capable of holding water.

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications.

The most common way to manufacture portland cement is through a dry method. The first step is to quarry the principal raw materials, mainly limestone, clay, and other materials. After quarrying the rock is crushed. This involves several stages. The first crushing reduces the rock to a maximum size of about 6 inches. The rock then goes to secondary crushers or hammer mills for reduction to about 3 inches or smaller.

The crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kiln.

The cement kiln heats all the ingredients to about 2,700 degrees Fahrenheit in huge cylindrical steel rotary kilns lined with special firebrick. Kilns are frequently as much as 12 feet in diameter—large enough to accommodate an automobile and longer in many instances than the height of a 40-story building. The large kilns are mounted with the axis inclined slightly from the horizontal.

The finely ground raw material or the slurry is fed into the higher end. At the lower end is a roaring blast of flame, produced by precisely controlled burning of powdered coal, oil, alternative fuels, or gas under forced draft.

As the material moves through the kiln, certain elements are driven off in the form of gases. The remaining elements unite to form a new substance called clinker. Clinker comes out of the kiln as grey balls, about the size of marbles.

Clinker is discharged red-hot from the lower end of the kiln and generally is brought down to handling temperature in various types of coolers. The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency.

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to ready-mix concrete companies to be used in a variety of construction projects and ‘wine egg amphoras’.

Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln.

I am sorry, I don’t give a dam about where or how my cement is made wether it is from China, Bolivia, Mexico, France? or England. It’s just dam cement, please do me a favor.

Now onto more interesting matters….vinous of course that is, and if you are still reading this blurbby bloggy blurb:..

We kicked off with the 2013 Malbec, Luna Austral

The wine has a dark violet hew, with reddish brilliance. Intense bloody nose, with plum, red and blackcurrants. On the palate the ripe menthol plums soften and show some elegant tannins. It has an excellent structure and persistence in the mouth.

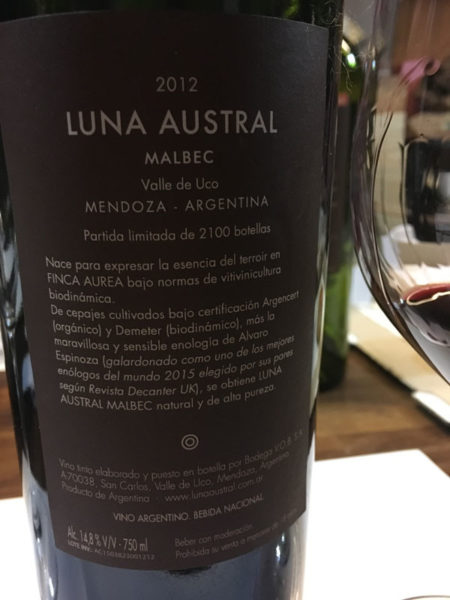

2012 Malbec Luna Austral

Very similar to the 2013, just a lot softer on the tannins, and shows that one year more of bottle age, can provide us a big Malbec with less aggressive structure. Still a big hitter, coming in at 14.8% of alcohol, as is the 2013. However, it is B-D alcohol and indeed it does kick a B-D punch, beware.

2013 Sintonia Luna Austral

This was an exquisite blend of 47% Merlot, 46% Cabernet Franc & 7% Malbec. With the clear signature of Alvaro Espinoza. It reminded me so much of our favorite Coyam (Emiliana), but made on the other side of the Andes. A totally hand made wine (hand crushed berries) with such definition and vitality, that even the 60U$D price tag that surprised me at first, but seemed to float away into the distance with vibrant fruits on offer, blended into an almost silky, well rounded hi-level wine. Only 1.600 bottles produced and for such a young pedigree, already showing a world class. Bravissimo!